Dr. Kim’s team provides 3rd party testing services using official standard methods: ASTM, ISO or TAPPI. This includes packaging material evaluation, analysis, and packaging structure development and testing.

All requests for 3rd party testing projects will be processed through the Center for Packaging and Unit Load Design. For a quote, please contact Dr. Kim directly.

Gas Barrier Property Measurement

Water Vapor Permeability Tester

Water vapor permeability is a measure of the passage of water vapor through the material. It is also known as water vapor transmission rate (WVTR) or moisture vapor transmission rate (MVTR). It is the mass of water vapor transmitted through a unit area in a unit time under specified conditions of temperature and humidity.

Oxygen Analyzer

The Oxygen barrier property is a key component of a packaging system to protect the products from oxidation. Oxygen permeability may vary with temperature, humidity, pressure and specimen thickness.

- Used for permeability analysis (OTR) for film, bottles and packages upon ASTM F2714-08

- Can be used for non-invasive and invasive measurements in oil, water and air

- Permits multiple measurements over time on the same package.

Headspace Analyzer

The PAC CHECK Systems are used in production, quality control, and R&D applications. Measure O2 or CO2 concentration with small sample amounts, manually or automatically. The same analyzer can be used for both flexible and rigid packaging. This instrument is certified traceable to NIST as an added feature for the quality conscious producer.

Thermal Analysis

Differential Scanning Calorimeter

The DSC measures heat flows and temperatures associated with changes in temperature in a material.

Dynamic Mechanical Analyzer

Measures the stiffness and damping properties of materials as the materials are deformed under stress.

Thermogravimetric Analyzer

The thermogravimetric analyzer is used to determine the change in a material's properties as temperature changes.

Rheology

Advanced Rheometer

Evaluation of rheological behavior of packaging material is crucial for developing new packaging materials and its structure. Intrinsic viscosity, melt viscosity, or relative viscosity is dynamically related to melt flow during processing.

- Creep and Recovery testing

- Stress relaxation testing

- Oscillation Frequency sweep, Oscillation strain sweep, Oscillation temperature ramp and sweep, flow testing, Multiwave frequency sweep

Viscometer

Determines the measure of viscosity for a lab specimen for a specific flow condition

Spectroscopy

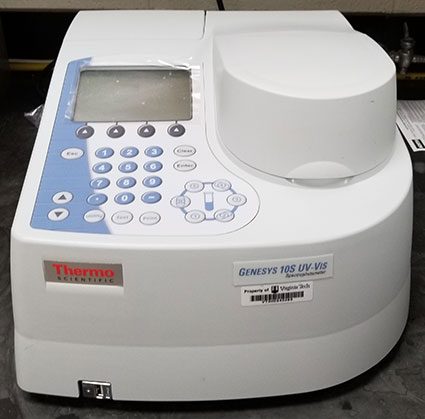

UV/Vis Spectrophotometer

The UV-Vis spectrophotometer utilizes a high-intensity xenon lamp and dual-beam optical geometry to deliver analytical data necessary for the study of a specimen.

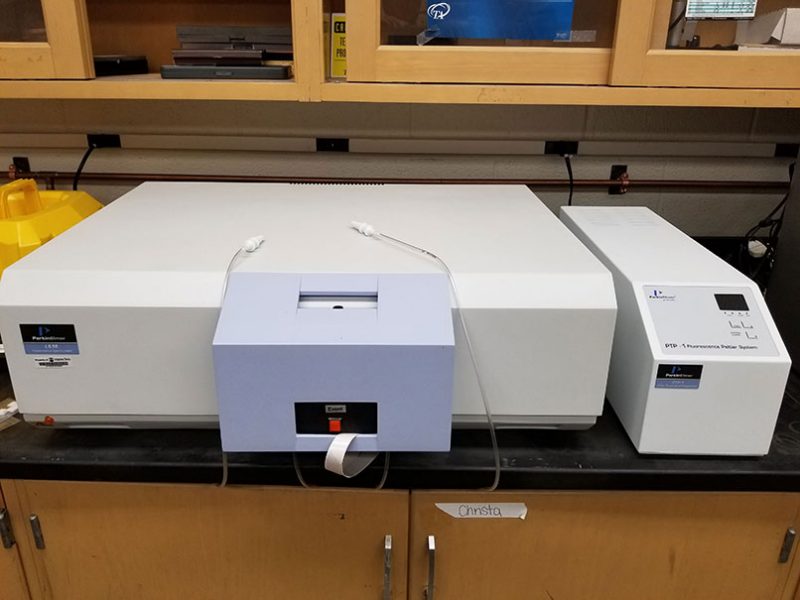

Fluorescence Spectrometer

The fluorescence spectromter uses spectroscopy to analyze the fluorescence of a lab specimen.

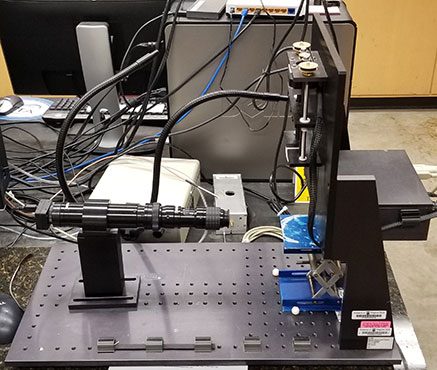

Fourier-Transform Infrared Spectrometer

Makes use of step-scan to perform FTIR spectroscopy experiments.

Other Analytical Testing

Leak and Seal Tester

Used for the quantitative determination of seal performance, seal quality, burst pressure, compression resistance, torsion force, and joint/disengaging force of flexible packages, aseptic packages, various plastic-pilfer-proof closures, flexible tubes, caps, and other materials

Contact Angle Tester

Used for determining the wetting characteristics of solid materials. Allows for the direct measurement opf surface tension, interfacial tension, and contact angles. Contact angle is a versatile technique used for the characterization of both liquids and solids.

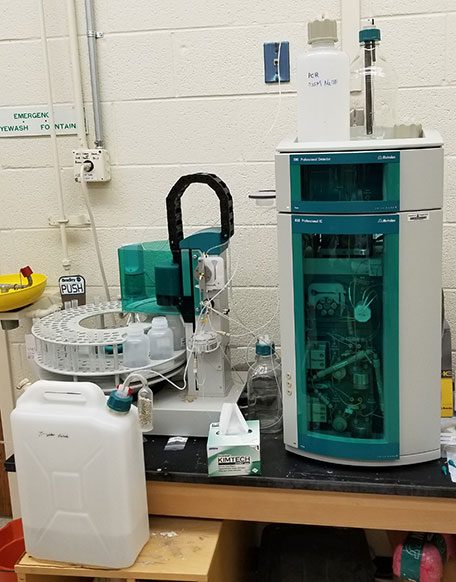

HPLC Tester

High-performance liquid chromatography is used to separate, indentify, and quantify each component in a mixture.

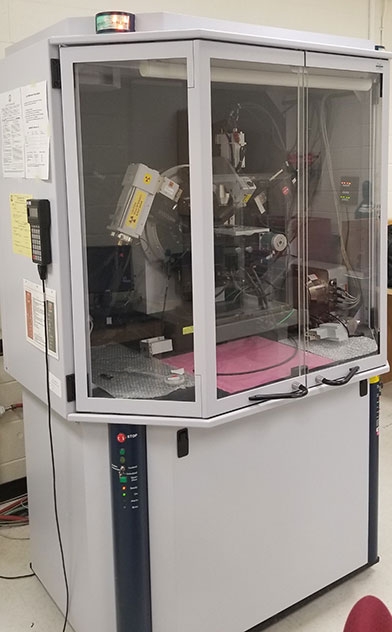

X-Ray Diffractometer

Using X-ray diffraction, the crystallinity of packaging polymers and ingredient is easily determined. The miscibility of composite materials can also be evaluated.

Miscellaneous

Mini DeBEE Homogenizer

Produces unmatched results in mixing, blending and size reduction of samples. Through the unique high pressure pumping system, the product is pumped out with high-velocity. Inside the emulsifying cell, the product experiences forces of shear, cavitation, and impact break, mix and blend -- producing a thoroughly mixed product with significantly smaller particles and a uniform distribution.

Benchtop Freeze Dryer

Used for lyophilizing sample loads. Its compact size makes it a flexible choice for the lab.

Centrifuge

This machine rapidly rotates and applies centrifugal force to its contents, typically to separate fluids or different densities or liquids from solids . The centripetal acceleration causes denser substances and particles to move outward in the radial direction, while less dense objects move to the center. It is important to keep and even balance when using the centrifuge.

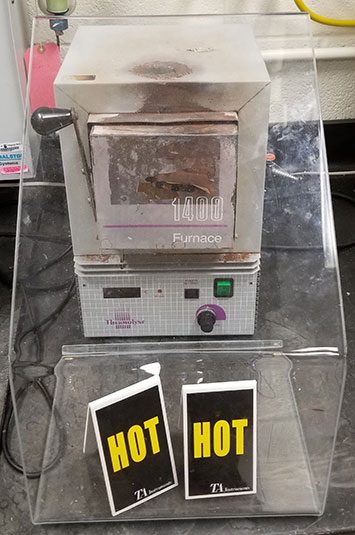

Muffle Furnace

Allows the use of high temperatures on specimens in a safely contained environment.

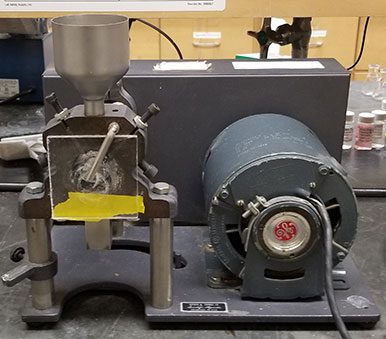

Wiley Mill

This mill prepares materials for analysis with minimal moisture loss through the process of grinding. This equipment allows the milling of various products, such as plastic.

Planetary Ball Mill

The extremely high centrifugal forces of a planetary ball mill result in very high pulverization energy and therefore short grinding times.

Relative Humidity Chamber

Wide temperature range of 0°C to 60°C enhances the flexibility of the unit. Relative humidity control via steam generator from above ambient to 95% at 37°C. Phenolic-coated evaporator for use in applications that create corrosive byproducts. Manual control of defrost and refrigeration cycles

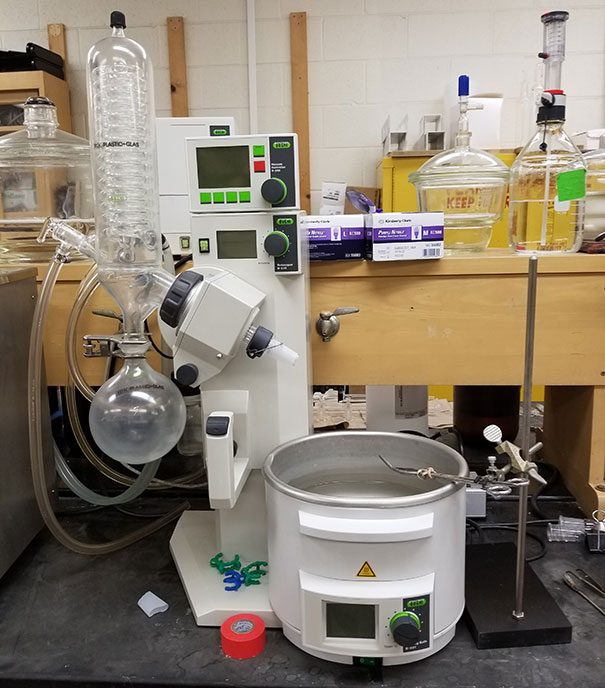

Rotary Evaporator

Used for the efficient and gentle removal of solvents from samples through evaporation. Careful application also allows removal of a solvent from a sample containing a liquid compound if there is minimal co-evaporation (azeotropicbehavior), and a sufficient difference in boiling points at the chosen temperature and reduced pressure.

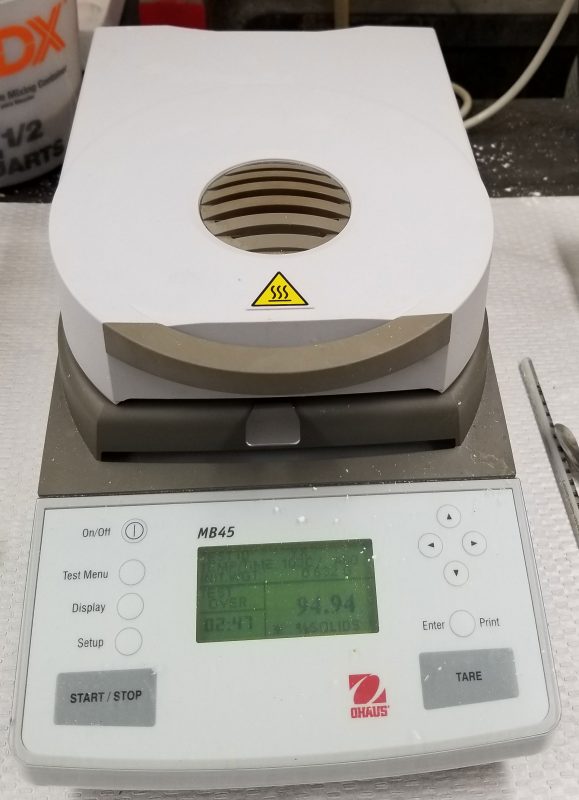

Moisture Content Analyzer

Combines state-of-the-art heating technology with high accuracy weighing technology to conduct quick and precise mosiuture analysis.

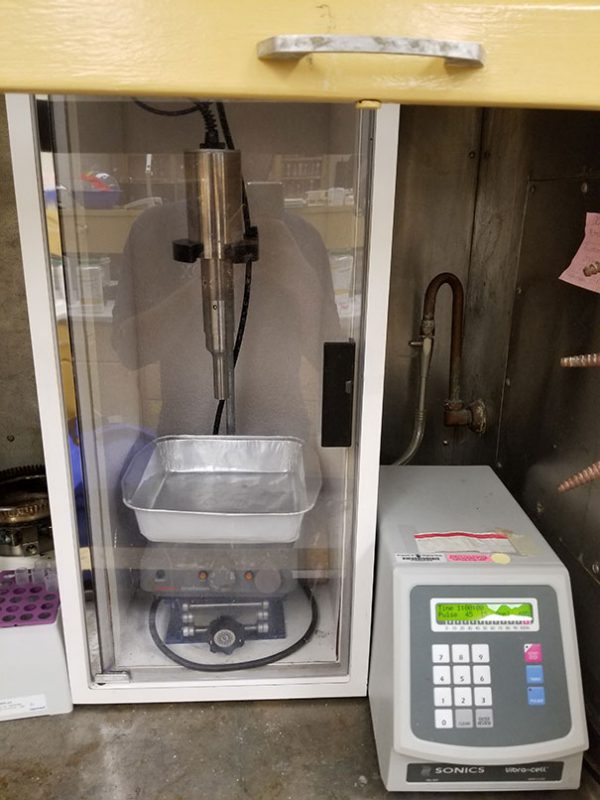

Ultrasonic Processor

Uses ultra-sonication to agitate particles in a sample for purposes such as the production of nanoparticles, biofuels, cell disruption, etc.

Injection Molder

Used to manufacture parts from materials such as plastic

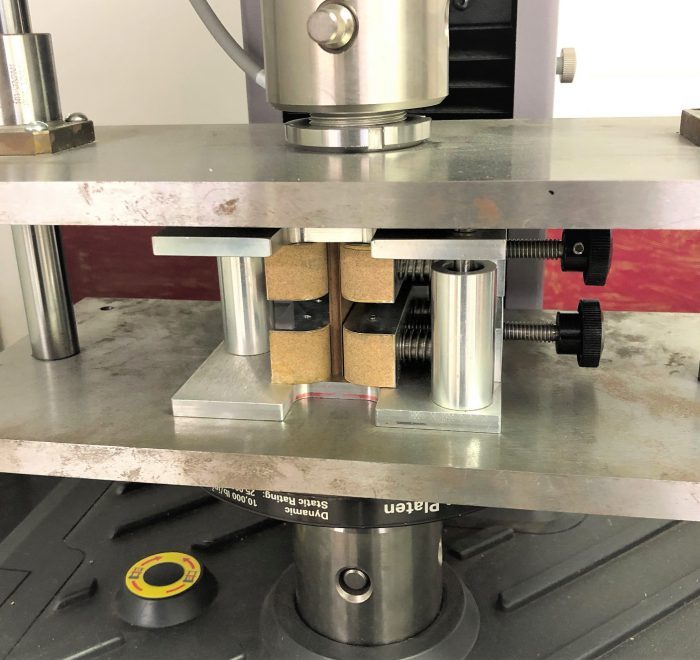

Crush Resistance Tester

Used to analyze the ability of a package or piece of packaging material to resist crushing forces such as those experienced during transport.